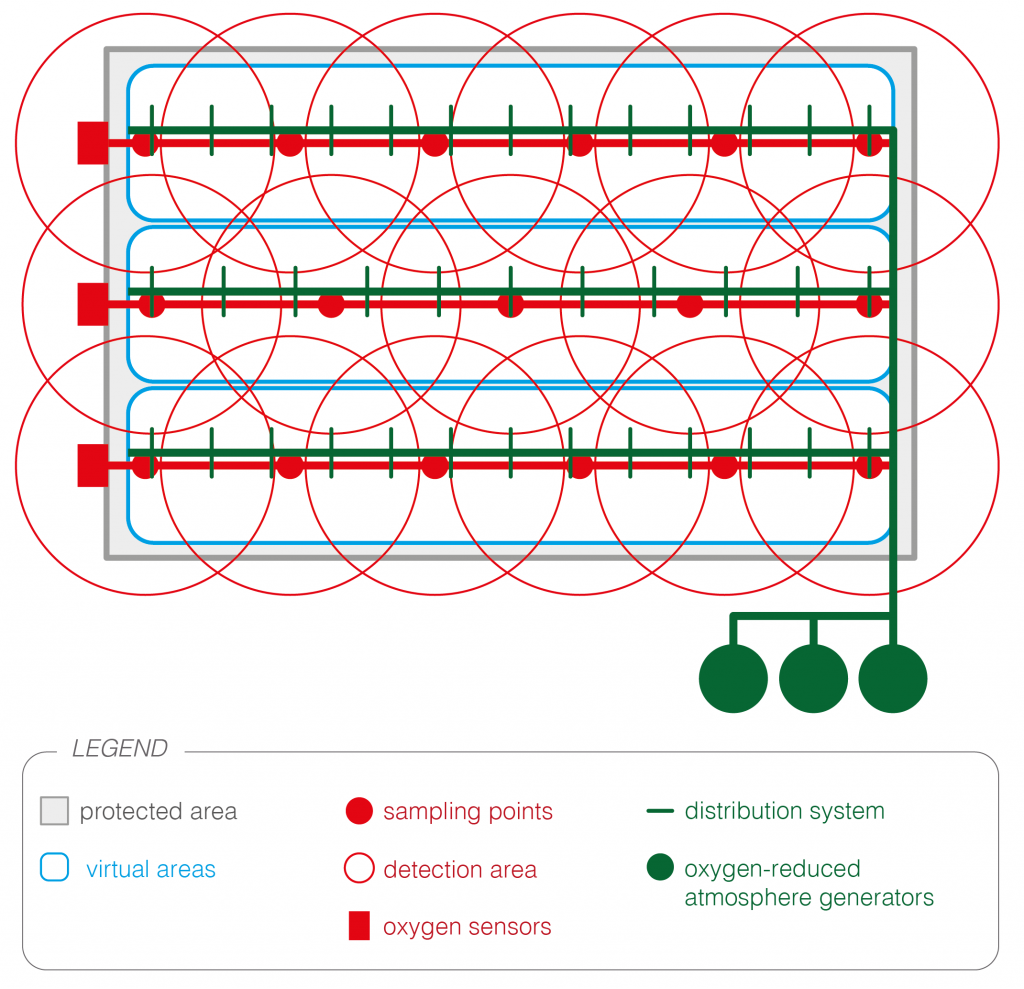

The variable-pitch virtual grid is another strength of our N2 ORS® system and forms an integral part. We have designed and patented it through relentless research and development work carried out over more than sixty years in the generated and controlled atmosphere sector.

The virtual grid makes it possible to optimise the resources used throughout the process of generating and distributing oxygen-reduced atmospheres. This grid enables a ‘virtual’ subdivision of the area to be protected into sections determined in the design phase, so that the oxygen-reduced atmosphere can first be analysed and then released.

Our customised analysis takes into account not only the standards that regulate analysis and release, but also a range of factors such as atmospheric parameters and the clearances and openings required for the passage of people and goods.

On the basis of the resulting mapping, pipes are laid for analysis and release, with the sampling and distribution points having a variable pitch: closer together in the perimeter area and further apart in the central area.

Advantages compared to a traditional analysis and distribution system

Causes of non-uniform oxygen concentrations

Solutions designed using the N2 ORS system

Strengths of the virtual grid

- optimise energy consumption and machine wear

- improves the mixing of inert gas with oxygen

- avoids the spread of oxygen detected throughout the entire area

- avoids the presence of non-uniform areas

- facilitates the detection of any critical points, enabling intervention in individual areas

- reduces the quantity of oxygen-reduced air to be released into the atmosphere

- using this sampling system, the early warning aspirating smoke detection (ASD) system required under the current reference standards can be easily integrated

The sampling and analysis system

The pipes installed for analysis of the area to be protected are fitted with sampling points, which constantly draw in the air and convey it to the corresponding sensors.

When a sensor detects an increase in oxygen levels compared to the limits set, it immediately transmits information to the control panel about the virtual area in which this increase has been detected.

The distribution system

When it has received the values from the sensor, the control panel verifies whether these values differ from the desired values and where necessary activates the generators, which produce the oxygen-reduced air. This oxygen-reduced air will be released into the compromised area, thus bringing the oxygen levels back within the set levels.

The synergies of the process

It is essential that the atmosphere to be protected comply with the necessary airtightness values: the virtual grid makes it possible to optimise both the analysis and release process and the work of the generators of the oxygen-reduced atmosphere, ensuring continuous control, a verified uniform distribution and lower management costs.