Home » Oxygen-reduced air generators

Generating

an Oxygen-Reduced

Atmosphere

Isolcell can produce all existing technologies

for creating an oxygen reduced atmosphere

ISOLCELL OXYGEN-REDUCED ATMOSPHERE GENERATORS:

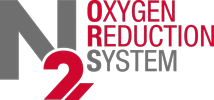

The generation of an oxygen-reduced atmosphere through molecular separation is achieved using ADOX® oxygen adsobers with VPSA (Vacuum Pressure Swing Adsorber) technology, NIMOS nitrogen generators with PSA (Pressure Swing Adsorber) technology, or ISOSEP membrane technology.

ADOX® SERIES

ADOX® Systems using VPSA technology

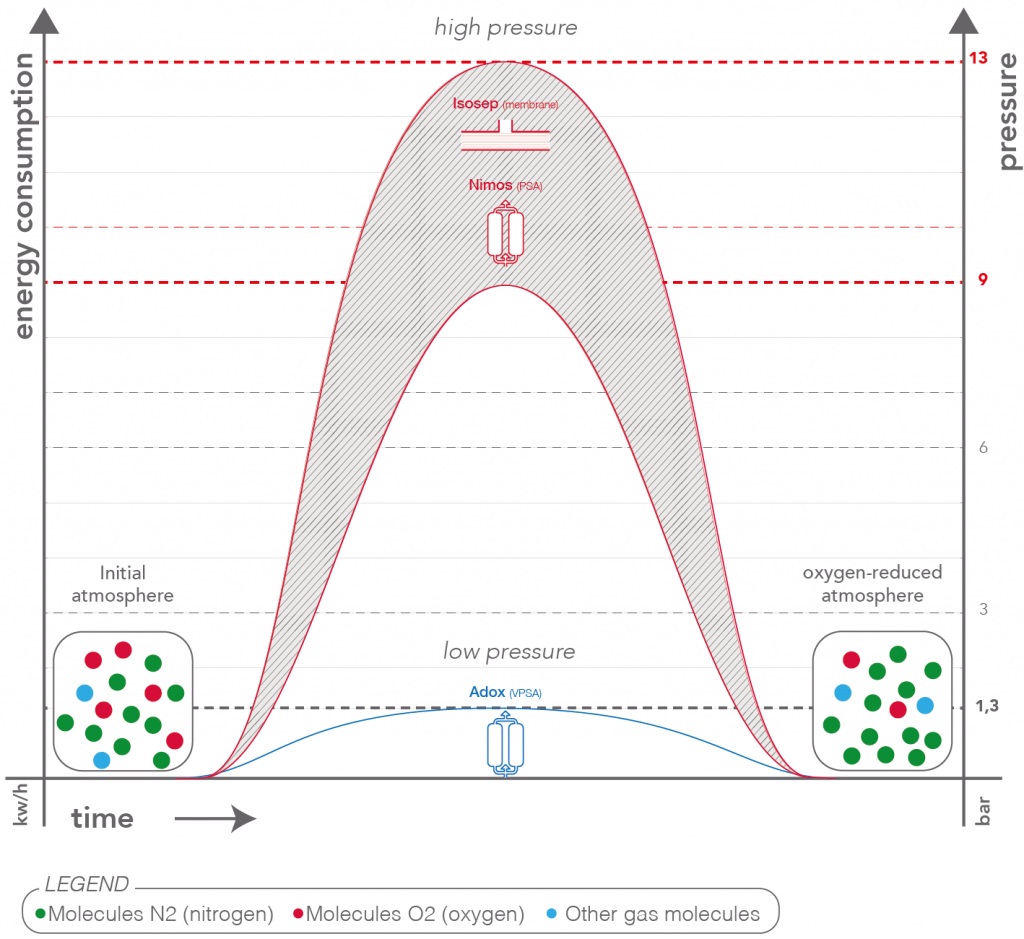

ADOX® systems (VPSA technology) are the most high-performance: these are modular systems developed specifically for fire prevention using oxygen reduction and guarantee greater safety, because they operate on the basis of redundancy. Thanks to its exclusive technology, ADOX® is able to operate at low pressure, significantly reducing energy consumption and wear.

This system is suitable for protecting medium-sized and large environments, optimising operating costs and achieving a saving of up to 60% compared to previous technologies.

Characteristics of the ADOX® system

Unlike high-pressure systems (PSA or membrane), which require a series of elements necessary for the compressed-air chain, ADOX® systems operate using low pressure and thus consume less energy compared to the two other technologies and require less maintenance. Furthermore, they are ready to use (plug & play) because they contain within them everything they need to operate.

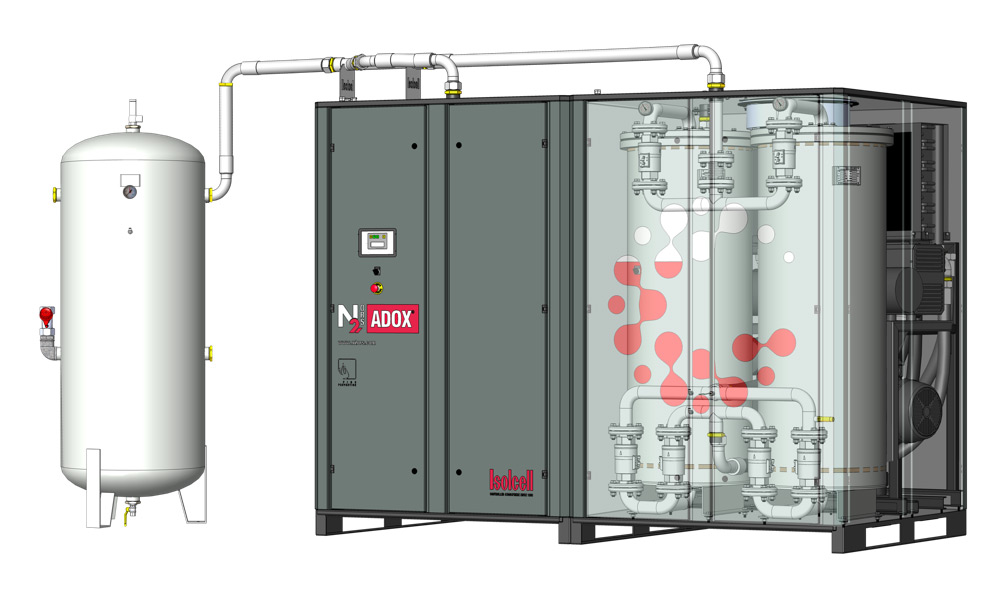

Modularity

ADOX® generators of self-extinguishing atmospheres are characterised by their modular composition. This means that their production capacity can be increased at any time simply through the addition of further modules. Improving the production capacity of these systems achieves a better optimisation of work cycles and energy consumption and, because of the redundancy system, more safety.

The figure represents an ADOX® oxygen adsorber made up of three independent modules.

In practice, it is like having three separate machines: if a module fails, the other two guarantee that the system operates correctly.

The quietest in the class

To improve the working environment, we have also worked on the system’s acoustic insulation, developing the sound-proof cabinet, providing shielding for the adsorber produced by combining materials of the highest quality.

This solution has resulted in a significant reduction in noise, from 90 to < 64 dB(A) (measurements of sound power taken and certified according to the UNI EN ISO 3744:2010 standard), thus obtaining the lowest level of noise in the category.

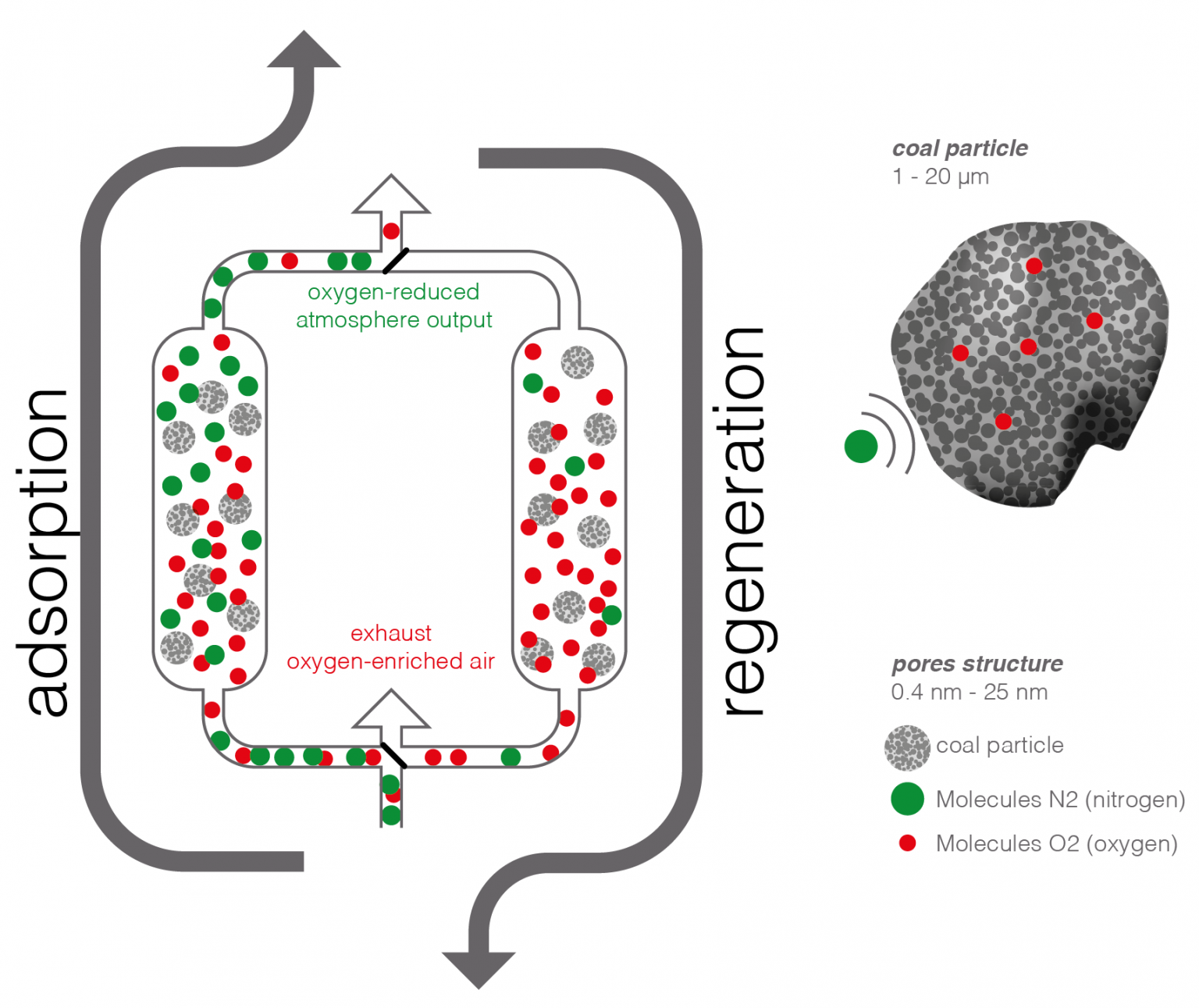

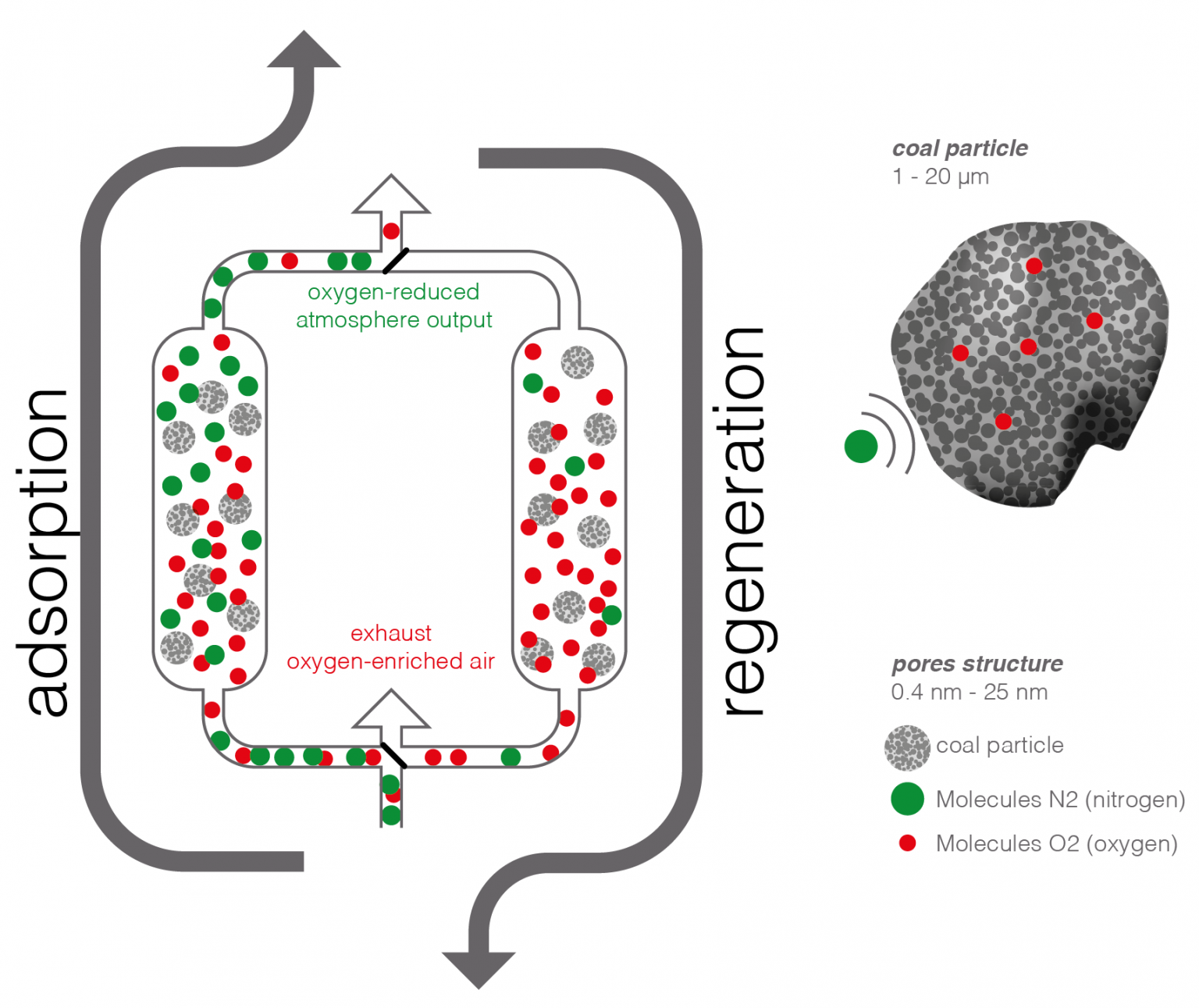

How the ADOX® system works

ADOX® N2 ORS® oxygen adsorbers use selective adsorption technology that enables the separation of oxygen molecules from nitrogen molecules: using a low-pressure compressor (max. 2.2 bar), air is delivered to tanks containing carbon-particle molecular sieves, which make it possible to adsorb the oxygen and to allow the nitrogen to pass through. While the separation phase takes place in one of the two tanks in the adsorber, the molecular sieves are regenerated in the other, removing the trapped oxygen using a vacuum-based process. This cycle is repeated continuously, making it possible to produce a high-quality self-extinguishing atmosphere at low cost, ensuring a continuous, steady supply.

NIMOS SERIES

NIMOS System using PSA technology

Nimos systems applying PSA technology use machinery that is installed in a designated room. Separation of the molecules requires high-pressure compressed air, as with membrane technology, and this entails increased energy consumption. However, this technology can be indicated when a compressed-air system is already present or when the position where these machines are installed is very far away from the area to be protected.

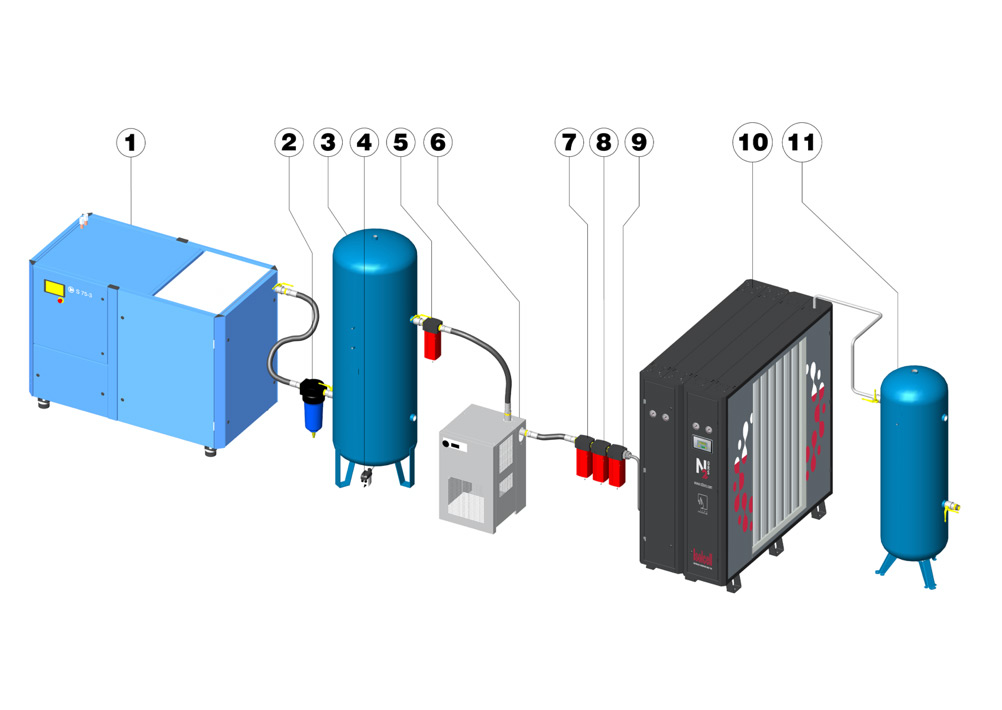

Elements in the Nimos system

For PSA technology, the following elements must be installed:

1. Compressor

2. Cyclone separator

3. Compressed air tank

4. Electronic condensate discharge

5. Universal filter

6. Air dryer

7. Fine filter

8. Micro filter

9. Activated carbon filter

10. PSA nitrogen generator

11. Process tank

How the Nimos system works

Nimos nitrogen generators using PSA technology, based on the principle of molecular separation, use specific activated charcoal filters to separate nitrogen from the oxygen present in the air. A flow of compressed air, previously dried and filtered, supplies the columns containing the sieves that filter the air inside the PSA generator.

The separation phase happens under pressure (from 6 to 10 bar). While one column is regenerated to eliminate the oxygen captured, another performs the separation by capturing the oxygen molecules and allowing the nitrogen molecules to pass through. The cycle repeats continuously, ensuring a continuous, steady supply.

The Nimos generators are completely automated, and are equipped with an oxygen analyser and a microprocessor that controls their operation.

ISOSEP SERIES

ISOSEP - System using Membrane Technology

Isosep systems (membrane technology) are appropriate for use in small spaces and can also be connected inside the area to be protected. However, they have higher energy consumption, but the ratio of consumption/supply of oxygen-reduced air and environment to be protected justifies their application.

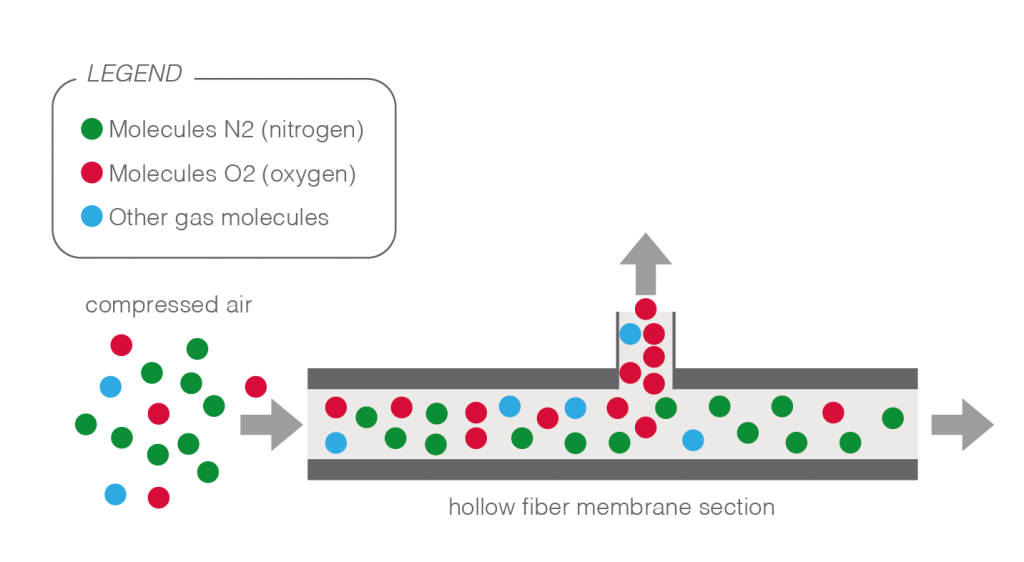

How the Isosep system works

While Nimos nitrogen generators and ADOX® oxygen adsorbers use molecular sieves to create a self-extinguishing atmosphere, Isosep generators use a high-pressure air compressor to drive the compressed air through the hollow-fibre membranes. This makes it possible to capture and expel the oxygen molecules, allowing the nitrogen molecules to pass through, as shown in the following illustration. The Isosep generators have been designed to protect small environments. Because of their ergonomic design, they can be easily installed inside the area to protect, optimising the use of space.

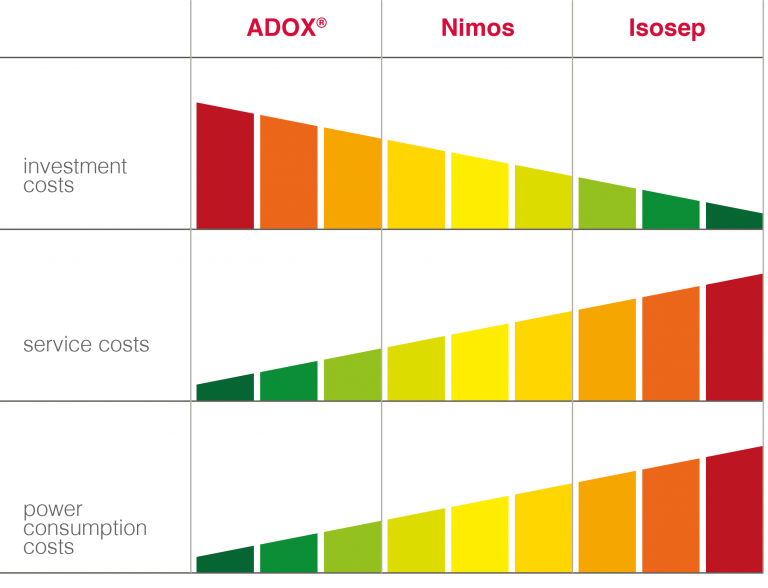

Comparison of technologies

It is clear that a significant saving in energy costs, obtained through the use of the right technology, can bring major benefits for the overall economy of the system. Among the various alternatives, it is therefore important to choose the option that will provide the greatest benefit over time.